Customizable SECC Electrolytic Galvanized Steel Automotive Bracket

Overview

Material: Aluminum, Iron, SECC Electrolytic Galvanized Steel

Manufacturing Process: Bending and Stamping Forming

Surface Treatment Options: Customizable (Options include Burnishing, Polishing, Zinc Plating, Nickel Plating, Copper Plating, Chrome Plating, Tin Coating, Powder Coating, E-coating, Blackening, Paint Spraying, PVD, Phosphating)

Company: Honlik Stamping Industrial Co., Ltd.

Website: Honlik Stamping Industrial Co., Ltd.

Email: jc@honlik-tech.com

Phone: +86-18059888145

Product Description:

The Customizable SECC Automotive Bracket by Honlik Stamping Industrial Co., Ltd. is a versatile solution designed for automotive control panel and loading system applications. Constructed from a combination of aluminum, iron, and SECC electrolytic galvanized steel, this bracket offers strength, durability, and corrosion resistance.

Manufacturing Process:

Crafted using advanced bending and stamping forming techniques, each bracket undergoes a meticulous manufacturing process to ensure precision and reliability. The process includes:

- Punching and Convex Punching

- Trimming and Punching

- Edge Flanging with Inner Hole Rounding

- Bending 1 with Hole Folding and Convex Punching

- Bending 2 with Edge Flanging and Die Pressing

- Overall Forming

Surface Treatment Options:

Customers have the flexibility to choose from a range of surface treatment options to meet their specific requirements. Options include Burnishing, Polishing, Zinc Plating, Nickel Plating, Copper Plating, Chrome Plating, Tin Coating, Powder Coating, E-coating, Blackening, Paint Spraying, PVD, and Phosphating. Each treatment offers unique benefits in terms of appearance and protection.

Application:

The Customizable SECC Automotive Bracket is engineered to provide reliable support and stability in automotive control panel and loading system applications. Its versatile design and customizable surface treatments make it suitable for various automotive environments.

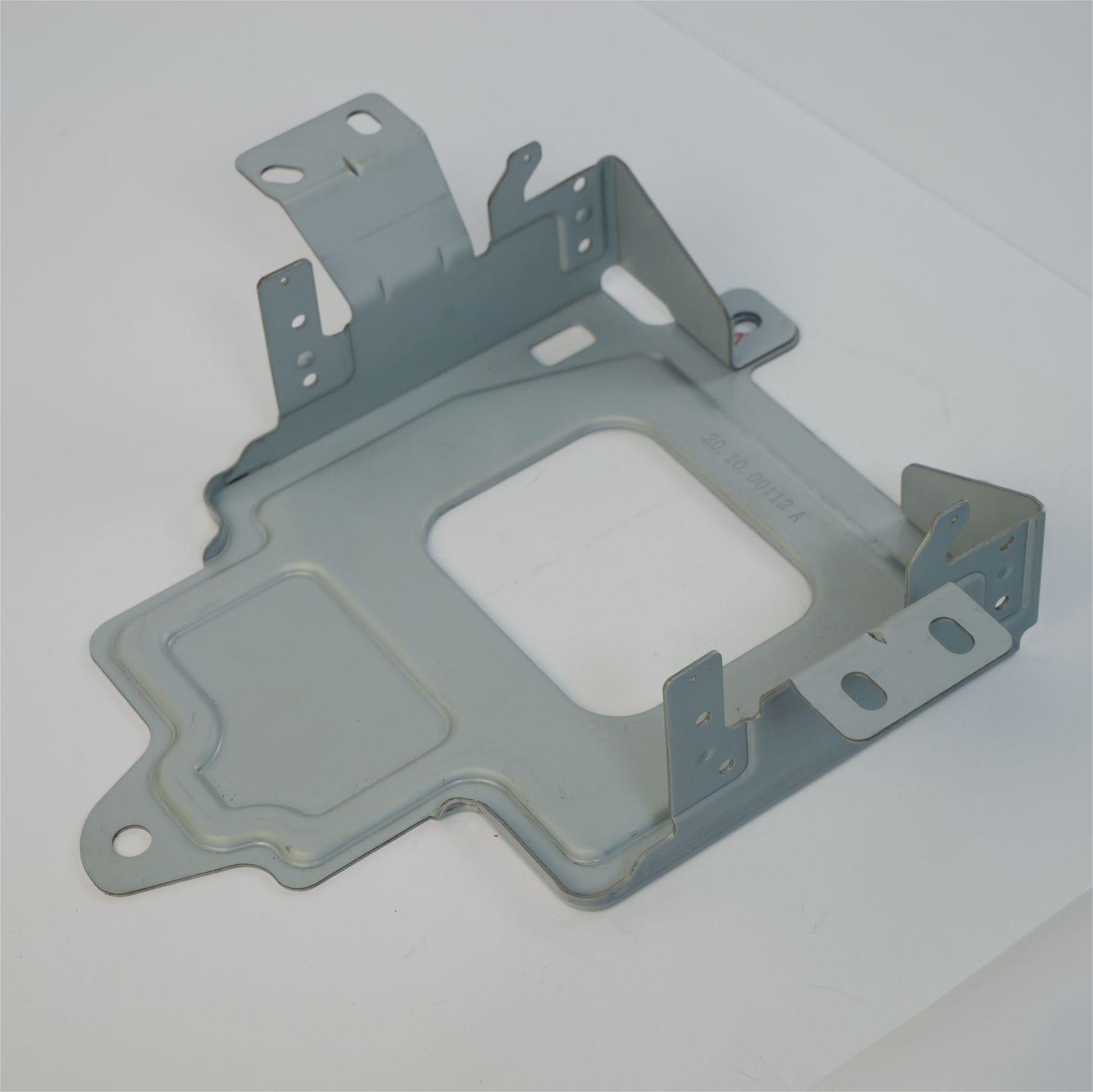

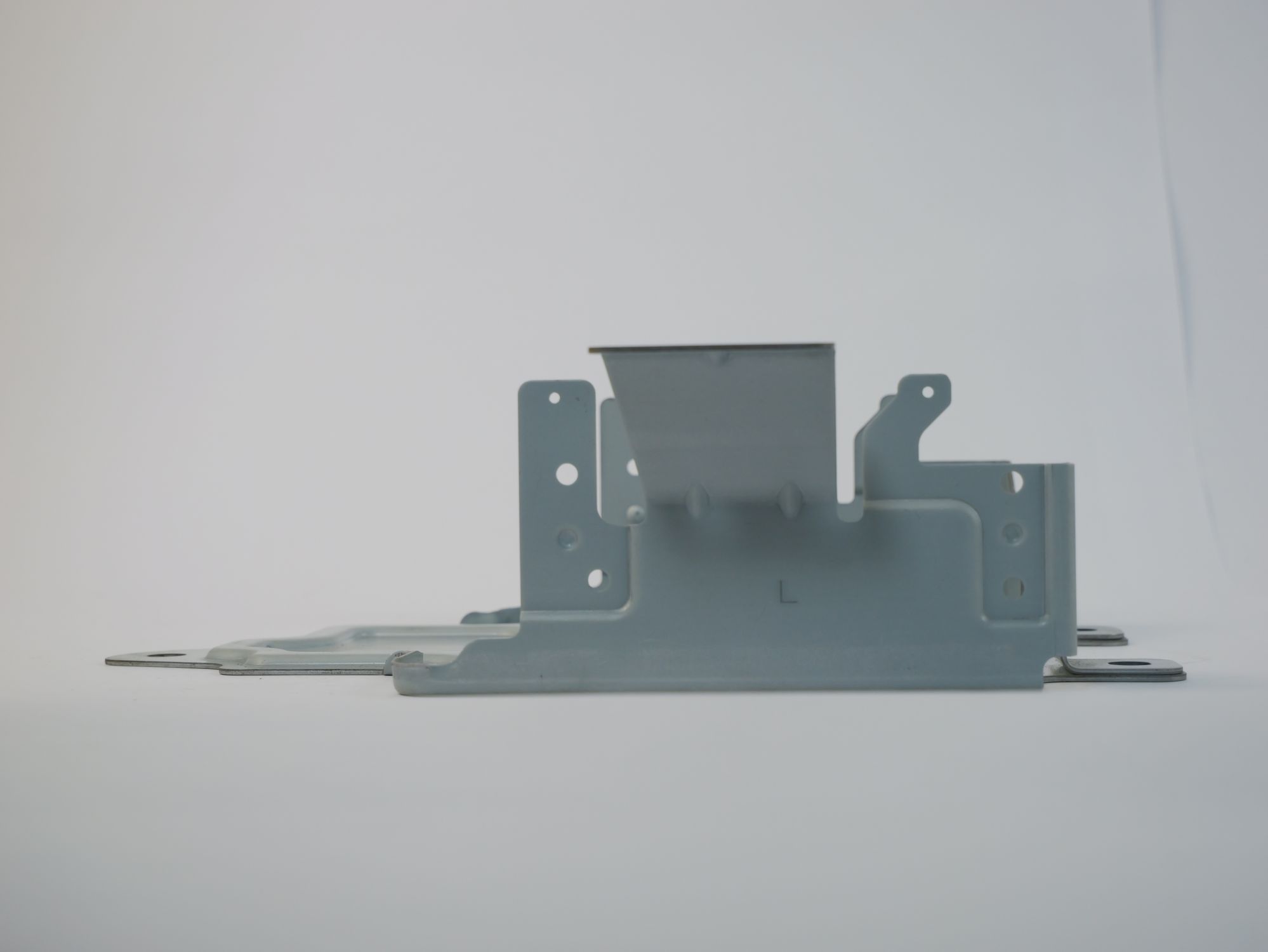

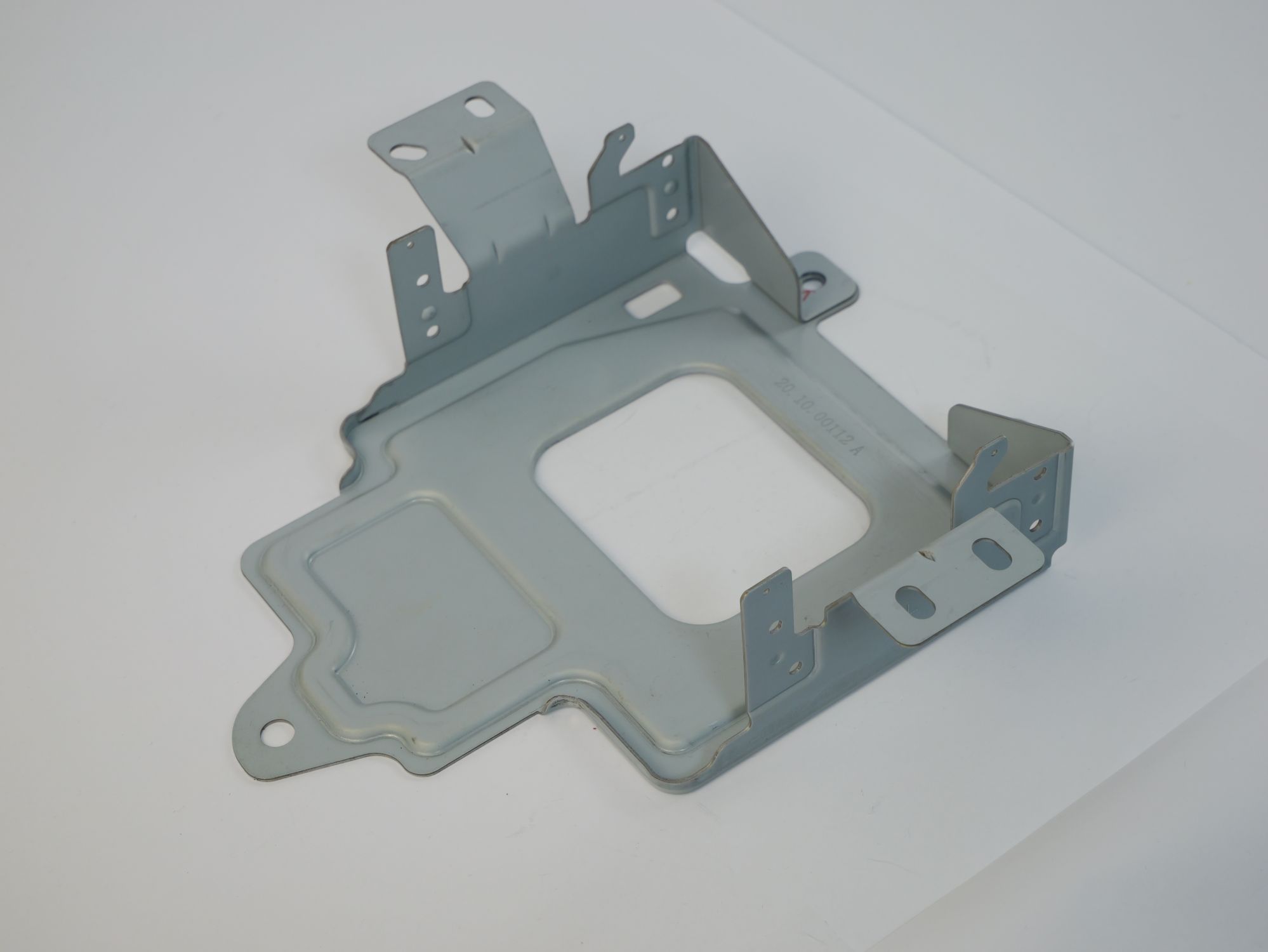

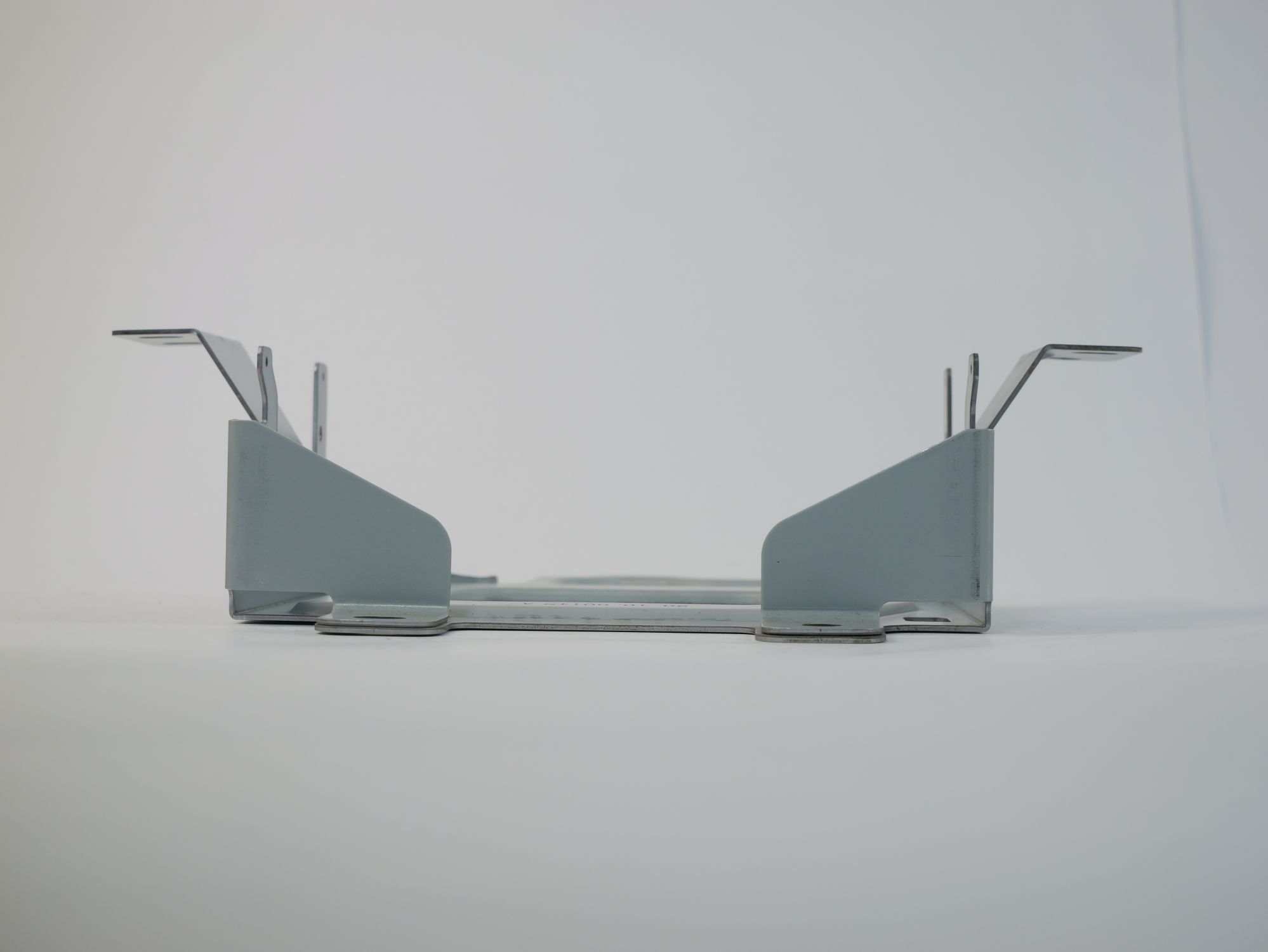

Product Images:

Below are images showcasing the Customizable SECC Automotive Bracket:

Why Choose Honlik Stamping Industrial Co., Ltd.?

- Expertise: With years of experience in metal stamping and forming, Honlik Stamping Industrial Co., Ltd. delivers high-quality products that meet industry standards.

- Customization: We understand the diverse needs of our customers and offer customizable solutions to meet their specific requirements.

- Quality Assurance: Our commitment to quality is evident in every product we manufacture. Rigorous quality control measures ensure that each bracket meets the highest standards of performance and durability.

For more information or to request a quote, please visit our website Honlik Stamping Industrial Co., Ltd. or contact us via email at jc@honlik-tech.com or phone at +86-18059888145.