How does a spring clip work? - custom manufacturers

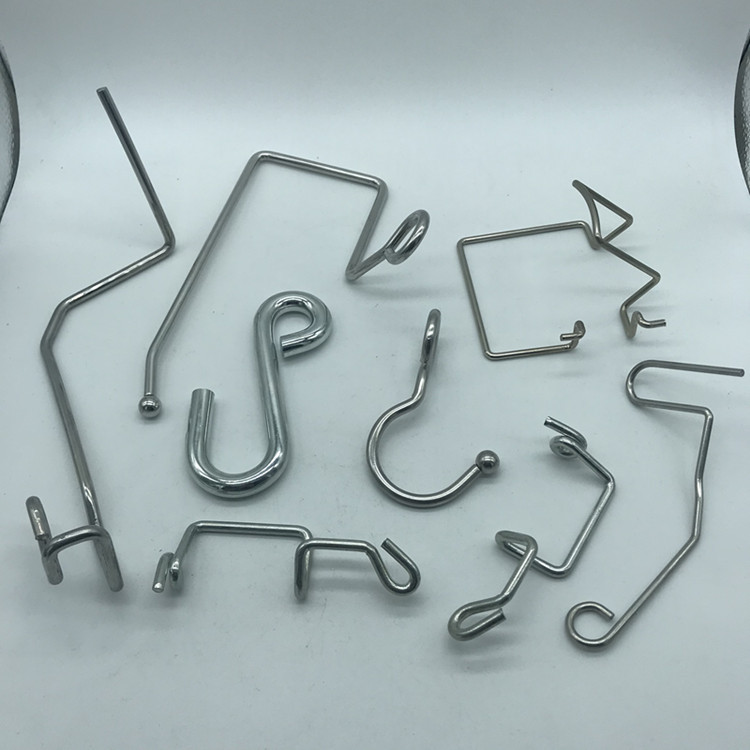

Spring clips are essential components in various industries, serving as reliable fasteners in applications ranging from mechanical assemblies to electronic devices. Understanding how a spring clip works is fundamental to appreciating its significance in modern engineering. A spring clip, typically made from high-quality materials like SUS304 stainless steel, functions by exerting a compressive or tensile force to secure components together. This article will delve into the mechanics of spring clips, highlighting their functionality, manufacturing processes, and the advantages of using SUS304 stainless steel in their production.

Spring clips operate on the principle of elastic deformation. When a force is applied to the clip, it deforms and stores potential energy. Once the force is removed, the clip returns to its original shape, releasing the stored energy. This elastic behavior is what enables spring clips to hold components securely in place. The design of spring clips varies, but they generally consist of a curved or coiled shape that can be compressed or extended to create a gripping force.

SUS304 stainless steel is a popular choice for manufacturing spring clips due to its excellent corrosion resistance, durability, and strength. Here’s a closer look at the manufacturing process:

Material Selection: SUS304 stainless steel is chosen for its superior properties. It contains a balanced composition of chromium and nickel, which enhances its resistance to rust and corrosion.

Wire Forming: The stainless steel wire is formed into the desired shape using specialized machinery. This process involves bending, coiling, and cutting the wire to create the specific configuration needed for the spring clip.

Heat Treatment: To enhance the mechanical properties of the spring clip, heat treatment is often employed. This process involves heating the wire to a high temperature and then cooling it rapidly, which increases its strength and elasticity.

Quality Inspection: Each spring clip undergoes rigorous quality inspection to ensure it meets the required standards. This includes testing for dimensions, elasticity, and overall performance.

Choosing SUS304 stainless steel for spring clips offers several advantages:

Corrosion Resistance: SUS304 is highly resistant to corrosion, making it suitable for use in harsh environments where exposure to moisture, chemicals, or salt can lead to degradation.

Durability: The material’s durability ensures that spring clips can withstand repeated cycles of compression and extension without losing their shape or function.

Strength: SUS304 provides the necessary strength to maintain a firm grip on components, ensuring secure fastening even under extreme conditions.

Elasticity: The elastic properties of SUS304 make it ideal for spring applications, allowing the clips to deform and return to their original shape repeatedly without permanent damage.

Spring clips find applications across various industries:

Automotive: In cars and other vehicles, spring clips are used to secure components such as hoses, wires, and brackets.

Electronics: They are commonly found in electronic devices to hold printed circuit boards (PCBs) and other small components in place.

Mechanical Engineering: Spring clips are used in machinery to fasten moving parts, ensuring they remain in position during operation.

Medical Devices: In medical equipment, spring clips are utilized for their reliability and biocompatibility, holding components together in precision instruments.

Customizing spring clips to meet specific requirements is a common practice. Honlik, a leading manufacturer of spring clips, offers tailored solutions to fit the unique needs of different applications. By working closely with clients, Honlik ensures that each spring clip is designed and manufactured to exact specifications, providing optimal performance and reliability.

When sourcing spring clips, it’s crucial to choose a reputable supplier like Honlik. With extensive experience in the industry, Honlik provides high-quality SUS304 wire forming spring clips that meet international standards. Their commitment to excellence ensures that customers receive products that are both durable and effective.

Understanding how spring clips work and the benefits of using SUS304 stainless steel is essential for anyone involved in engineering or manufacturing. Spring clips play a vital role in securing components across various industries, and their reliability is crucial for the overall performance of systems and devices. By choosing high-quality materials like SUS304 and working with trusted manufacturers like Honlik, you can ensure that your spring clips will provide the necessary support and longevity required for your applic