Honlik - Custom Auto Bracket Experts

In the automotive industry, precision and durability are non-negotiable. Honlik, a leading manufacturer based in China, has emerged as a trusted name in Custom Automotive Brackets, offering tailored solutions that redefine reliability and performance. With a focus on SECC Electrolytic Galvanized Steel Brackets and Bending and Stamping Forming Parts, Honlik delivers OEM Automotive Bracket Solutions that meet the stringent demands of modern vehicles.

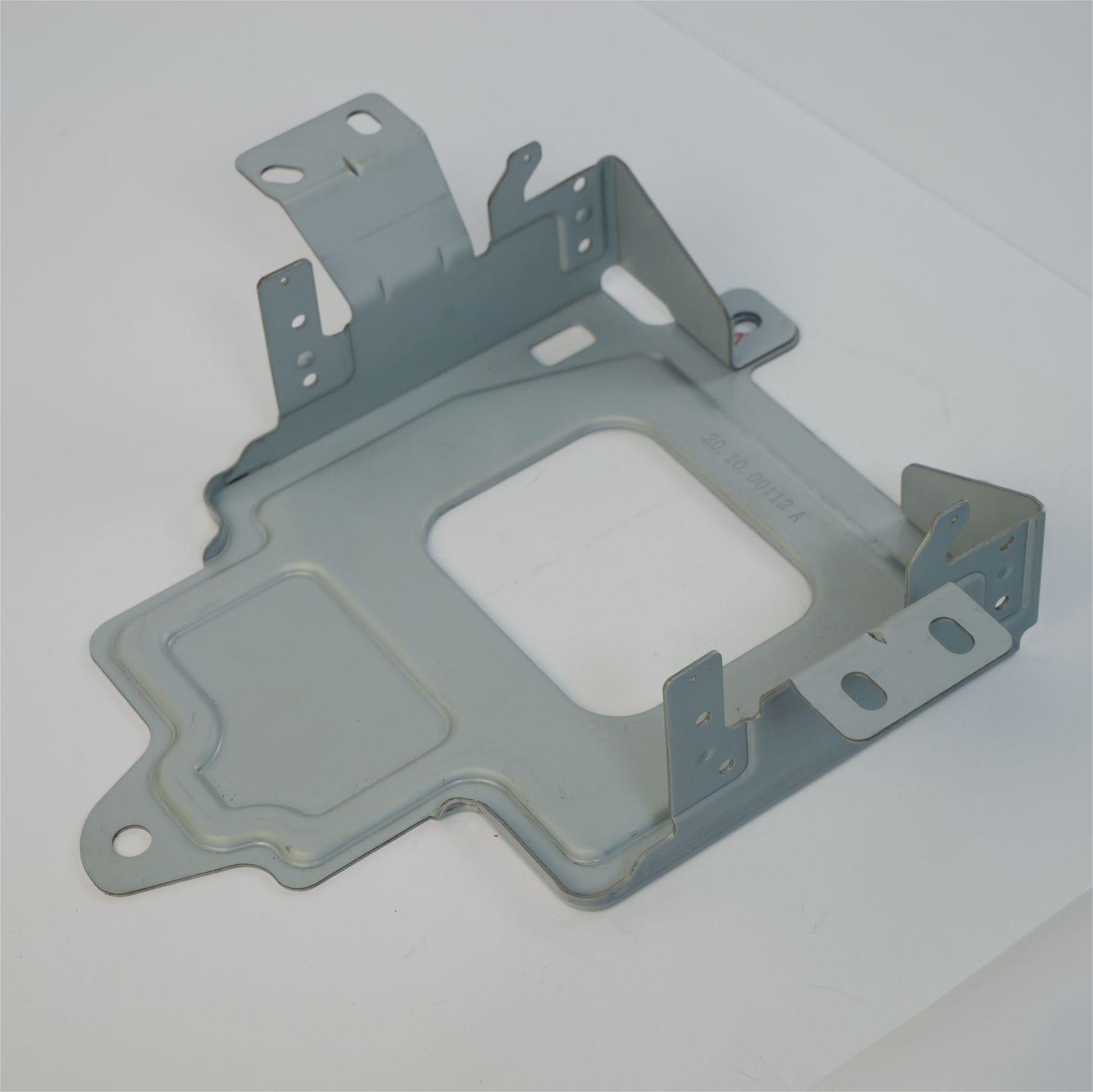

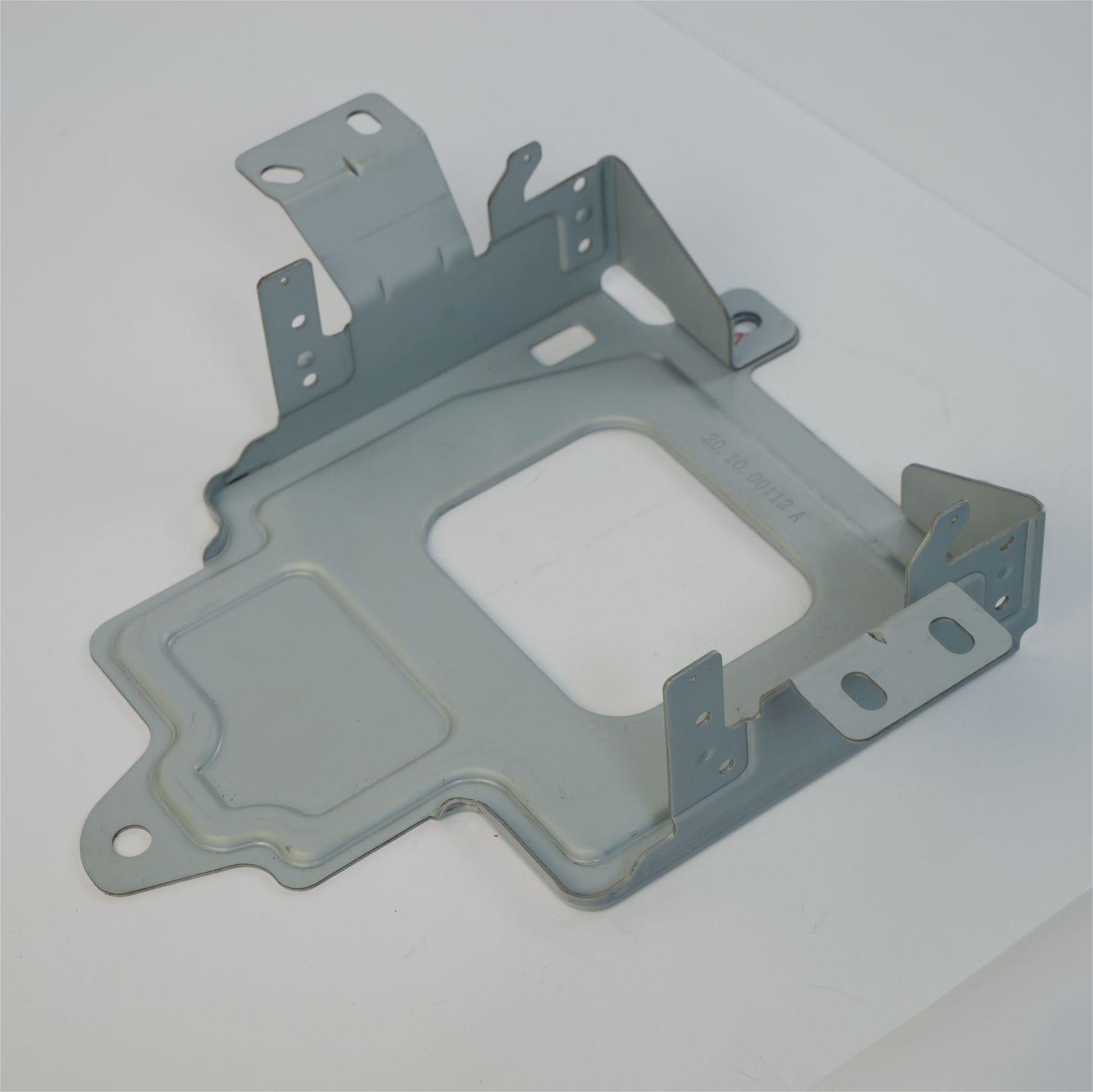

Honlik’s Custom Automotive Brackets are engineered to seamlessly integrate into diverse automotive systems. Whether for engine mounts, chassis reinforcements, or interior components, their brackets are designed with meticulous attention to detail. By leveraging advanced CAD/CAM technologies, Honlik ensures each bracket aligns perfectly with client specifications, from load-bearing capacities to dimensional tolerances. This custom approach empowers automakers to optimize vehicle designs without compromising on structural integrity.

The cornerstone of Honlik’s product line is their SECC Electrolytic Galvanized Steel Brackets. Manufactured from premium SECC steel, these brackets offer exceptional corrosion resistance, ensuring longevity even in harsh environments. The electrolytic galvanization process creates a uniform zinc coating that adheres tightly to the steel substrate, providing superior protection against rust and wear. This makes Honlik’s brackets ideal for applications where durability is critical, such as underbody components or exterior accessories.

Honlik’s expertise in Bending and Stamping Forming Parts further sets them apart. Their state-of-the-art stamping presses and bending machines enable the production of complex geometries with unmatched precision. From intricate flanges to reinforced ribs, every feature is engineered to enhance structural performance while minimizing material waste. This capability allows Honlik to deliver brackets that are not only robust but also lightweight, contributing to improved fuel efficiency and vehicle dynamics.

As an OEM Automotive Bracket Solutions provider, Honlik’s value proposition extends beyond product quality. Their China-based facilities offer unparalleled flexibility, accommodating both small-batch prototypes and high-volume production runs. This agility is complemented by a dedicated team of engineers who collaborate closely with clients to refine designs, optimize materials, and accelerate time-to-market. Their commitment to custom solutions ensures each bracket is tailored to the unique requirements of the vehicle, whether for passenger cars, commercial trucks, or electric vehicles.

Honlik’s manufacturing processes adhere to the highest international standards, including IATF 16949 certification. Their rigorous quality control measures, from raw material inspection to final product testing, guarantee that every bracket meets or exceeds client expectations. This focus on excellence has earned Honlik the trust of leading automakers and Tier 1 suppliers worldwide.

In addition to standard brackets, Honlik excels in bespoke designs. Their R&D team continuously explores new materials and manufacturing techniques, enabling clients to incorporate innovative features such as vibration damping, thermal insulation, or integrated sensors. This commitment to innovation ensures Honlik remains at the forefront of automotive bracket technology.

Honlik’s competitive edge is further strengthened by China’s robust manufacturing ecosystem. By leveraging local supply chains and skilled labor, they deliver cost-effective solutions without compromising on quality. Their global reach, supported by a network of distribution partners, ensures clients worldwide benefit from Honlik’s cutting-edge capabilities.

In conclusion, Honlik’s Custom Automotive Brackets, SECC Electrolytic Galvanized Steel Brackets, and Bending and Stamping Forming Parts exemplify their dedication to excellence. With a focus on OEM solutions and China’s manufacturing prowess, Honlik continues to set new benchmarks in automotive bracket technology. Their customer-centric approach and commitment to innovation make them the ideal partner for automakers seeking to elevate their products with durable, high-performance brackets.